The difference

WHY BLUECON?

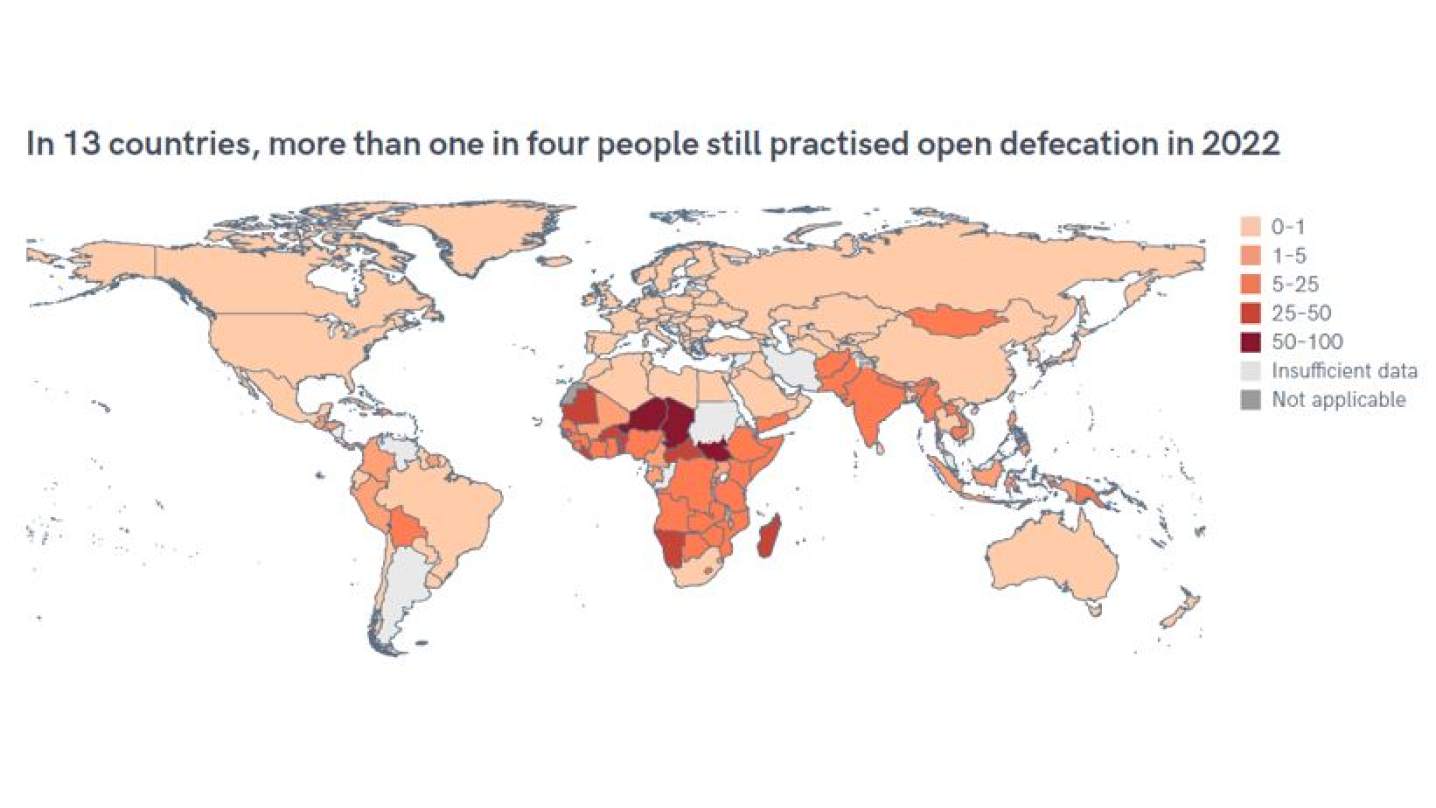

🌍 Global sanitation gap – 80% of domestic wastewater remains untreated

Bluecon provides off-grid, decentralized treatment where no infrastructure exists, giving remote and underserved communities access to safe and sustainable sanitation.

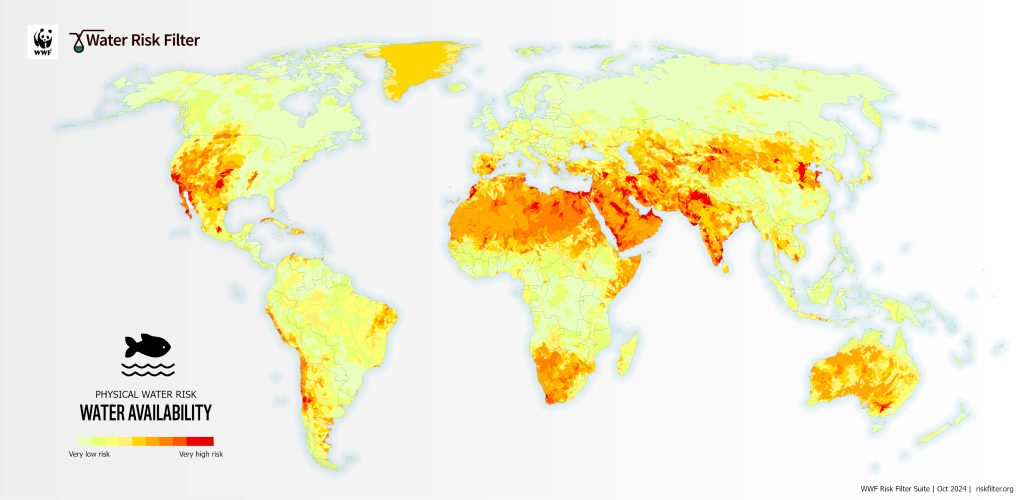

💧 Water scarcity & reuse – enabling safe local reuse for irrigation, toilets, or industry

By turning wastewater into clean process water, Bluecon supports local reuse and helps reduce dependency on drinking water sources, even in drought-prone regions.

🌪 Climate resilience & flood-prone areas – operational during heavy rain or rising water levels

Our systems can be elevated, relocated, or protected from flood damage, ensuring continuous operation in high-risk zones and protecting the environment during extreme weather.

⚠️ Failing or overloaded treatment works

Bluecon units can operate as a full replacement or as a modular extension to support failing WWTPs — ideal for emergency upgrades, population growth, or temporary relief during refurbishments.

📑 Compliance with strict discharge regulations – including ammonium and phosphate limits (EU directives 91/271 and 2020/741)

With advanced physical-chemical treatment, we meet demanding nutrient discharge limits, giving industries and developers the tools to meet permit conditions and avoid fines.

♻️ CO₂ footprint reduction & sustainable operation

Bluecon uses low-energy processes and enables shorter water cycles, contributing to your carbon reduction goals — including circular economy, ESG targets, and net-zero ambitions.

🏘 Circular water loops in urban development

By treating and reusing water within housing projects or commercial zones, Bluecon enables water-smart developments that can move forward even without access to central infrastructure.

🚨 Emergency response & rapid deployment

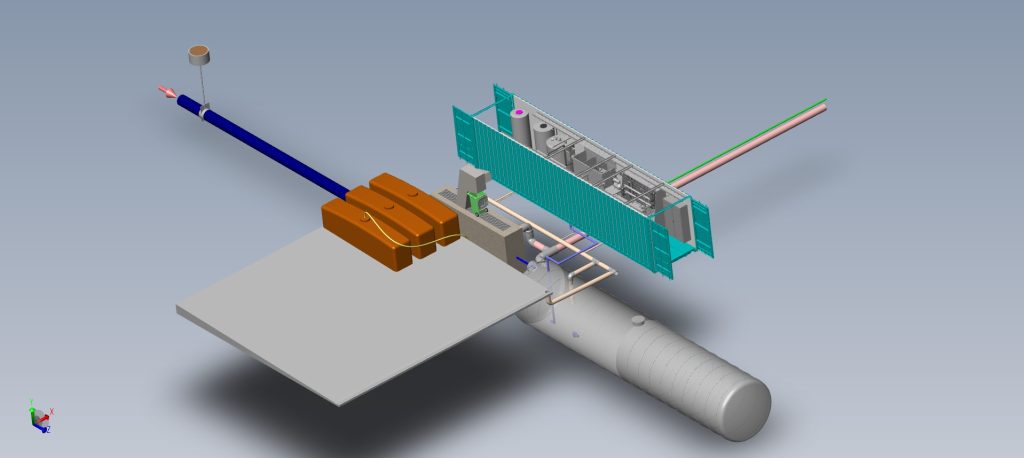

Our plug-and-play containers are fully preassembled and can be deployed within days — ideal for natural disasters, refugee camps, or urgent replacement of broken treatment systems.

Bluecon solutions

“Local Dutch answers to global water challenges.”

Around the world, billions of people still lack access to proper wastewater treatment. In many regions, centralized biological treatment plants are overloaded, outdated, or simply no longer functioning. Septic tanks, once seen as a low-cost alternative, often leak, pollute groundwater, and pose serious health risks — especially in rapidly growing or unregulated areas. In even more remote parts of the world, there is no sanitation infrastructure at all.

Raw wastewater flows untreated into rivers, lakes, or the sea, threatening ecosystems and public health.

On top of this, climate change is intensifying the risks. Flood-prone regions face increasingly frequent and severe weather events. In these situations, traditional sewage systems and treatment plants often fail, leading to environmental disasters and uncontrolled contamination. At the same time, rural communities, eco-resorts, and off-grid developments are growing in areas where infrastructure simply can’t keep up.

This is where Bluecon makes the difference. Our decentralized, modular wastewater treatment units offer a robust, odour-free, non-biological solution that can be placed wherever it’s needed!

From urban flood zones to the most remote locations. Whether replacing a broken treatment plant, providing safe reuse water for irrigation, or preventing pollution in a vulnerable area, Bluecon enables communities and industries to take control of their water, today and for the future.

There are 1001 reasons why almost 80% of global rural waste water is still being disposed untreated. Let's end this, now!

Scalable

500 – 5,000 inhabitants per unit (cost-effective up to >20,000)

Sustainable

Low in energy consumption and NET-zero proof

Hybrid ready

Perfectly suited for hybrid situations on existing biological WWTP's. Either to assist, replace or add-on the treatment processes. Also suitable to colaborate with "wetlands" for a better carbon footprint

Adaptive modular system

Depending on the recieving goal of purified wastewater, the technical design is tailored to the clients demands. Clean disposable water, irrigation water or even the quality of drinking water. Everything goes!

Easy Installation and Operation

Ready for operation with minimal setup time and without highly educated staff

Quiet, emission- and odor safe labor

A clean and safe working area, environment and water cycle

All round

Low investment in infra, decentralised with short distance pipelines. Suited for cities, areas, villages and rural municipalities.

Climate proof

Suited in cold, hot, dry and even wet and flooded situations (optional).

Safe for circular water

Non-biological monitored operation for stable effluent quality. Reduces pressure on drinking water supplies, ensuring safe reuse 24/7/365. Enhanced options for circular water management in construction adn hospitality sites like eco-resorts and hotels.

Solutions

FROM WASTEWATER TO RE-USABLE WATER

Our vision is to optimize the water cycle by developing a method which enables wastewater to be treated into clean, reusable water. Bluecon was founded to unlock the potential of wastewater for sustainable development by resolving the issues around small scale wastewater treatment in regions worldwide

Being able to reuse wastewater for sustainable development will change the world of waste water treatment to enhance the quality of life of local communities.

“At Bluecon, our mission is to revolutionize wastewater treatment with our dedicated partners through innovative, decentralized solutions that provide sustainable, high-quality water management for communities and businesses. We are committed to promoting environmental stewardship, enhancing resource conservation, and supporting the growth of smart, resilient infrastructures worldwide.”

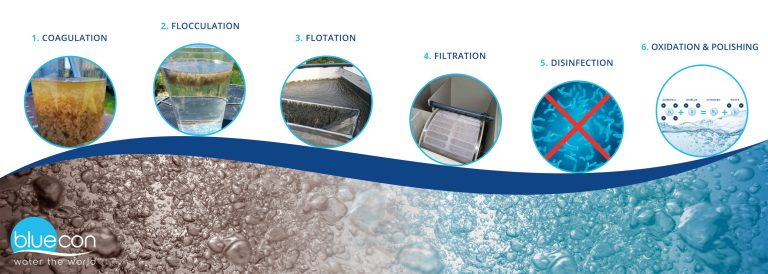

The Process

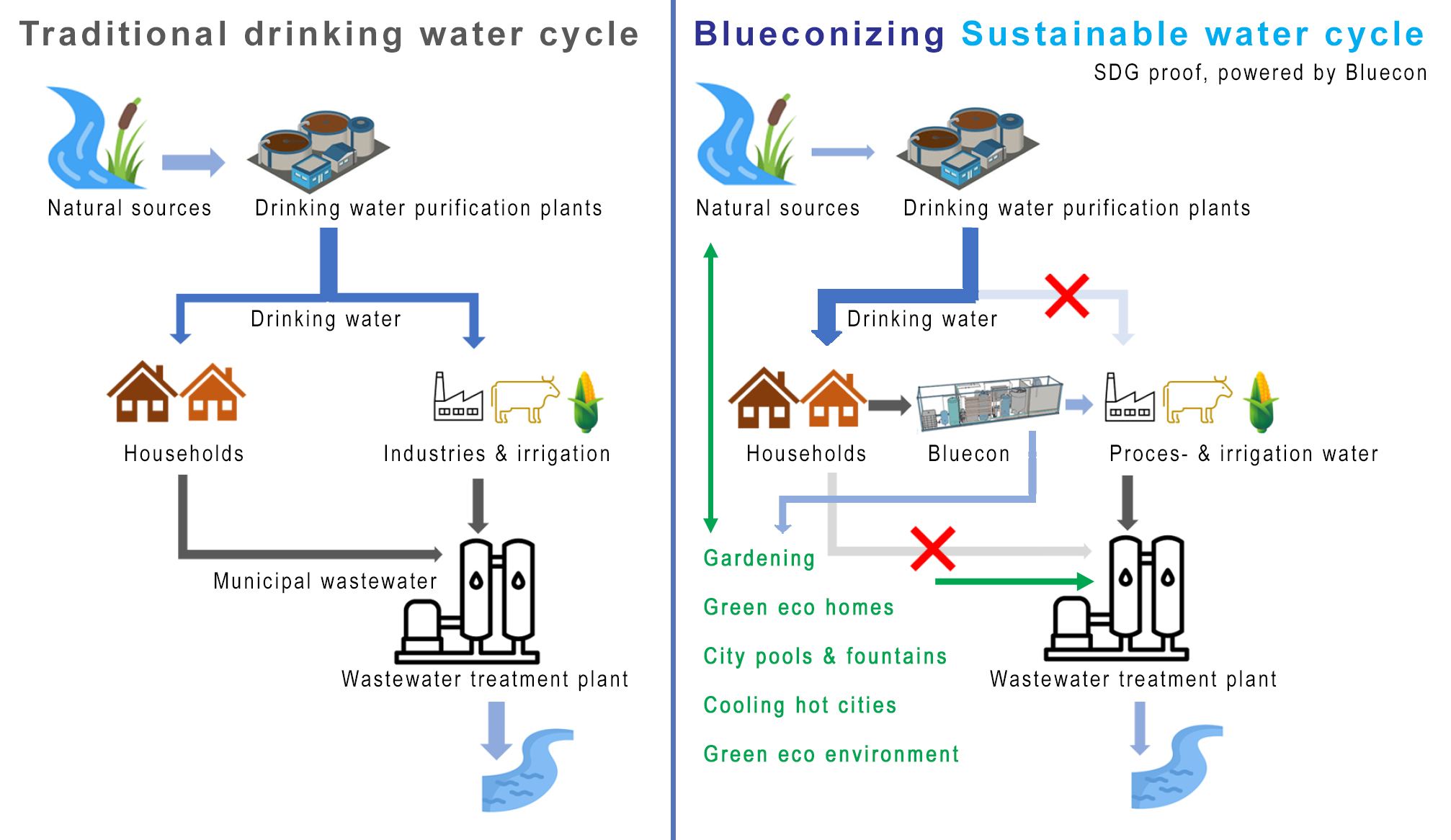

Blueconizing

Bluecon engineers developed a unique treatment process that convert sewage water of domestic origin into clean reusable water. “Bueconizing” is an innovative physical technology to treat wastewater without use of bacteria. In a few steps domestic wastewater is converted into clean surface water or irrigation water.

This is a 100% physical wastewater treatment, that achieves an unprecedented high degree of purity. After “blueconizing”, the water meets the most stringent requirements for clean surface water.

Compact, plug and play water treatment solution for a few people or up to 10.000 inhabitants

Robust system that is easy to operate and low in maintenance

Up to 50% lower in OpEx (labour, energy, maintainance) than the traditional biological wastewater treatment

Built in weeks and installed in days

Providing safe re-use of water any time any day

Flotation, a nano-bubble technology after coagulation and flocculation plays a dominant role in the Bluecon wastewater treatment process.

How

- After removal of coarse material in the pre-screen, wastewater is treated in the first process step: coagulation. Wastewater is destabilized on molecule level to form flocs. A coagulant (iron or aluminium salt) is used to neutralize the charge and induce coagulation of the impurities. This process is controlled by sensors and smart software.

- For maximum removal of the coagulated impurities, a special eco-friendly polymer is added. This is called the flocculation Al impurities are glued together to form big flocs (sludge) resulting in a clear water phase with low turbidity.

- In the Bluecon flotation module the sludge is separated from the water. A unique process with micro bubbles lifts the sludge to the surface of the flotation tank for mechanical removal with a skimmer. The sludge is collected in a sludge buffer and ready for dewatering without any further pretreatment. COD, BOD, TSS, phosphate and organic nitrogen are removed.

- Water from the flotation is filtered in a two-step operation to take out micro flocs and other small particles like micro plastics and paper fibres. A project suited precision filter takes out the larger flocs (1-5 mm) and acts as a safeguard for the flotation process. A sand filter filters down to sub-micron level to take out the smallest suspended solids.

- In the ammonium oxidation module ammonium-nitrogen is removed to any desired level, regardless of the influent level, water temperature or climate. A special oxidation agent, OxiBlue, oxidizes the ammonium to nitrogen (g). The oxidation agent disinfects the water and is ready for direct and safe re-use. Sensors control the module and provide online data for 24/7 monitoring of water quality.

- In cases where the influent wastewater is very extraordinarily polluted or there are strict effluent requirements, several polishing modules can be installed. With ozone, UV solutions and adsorbents, COD/ BOD levels are optimized. These modules can be applied to remove substances like medicines, hormones and PFAS.